Packaging Trends in Logistics – Growth Ahead for Machine Vision

The strategy department of the German-based logistics giant DHL has released a new trend report about packaging in logistics. It provides valuable insights into market sizes with their regional shares. The trend analysis of new requirements on packaging for goods and logistics provides insights on growth rates and new demands for Machine Vision systems for packaging applications.

Production and Application of Packaging – Highly Automated, Demanding, and … Changing

Packaging is one of the key application areas of Machine Vision. Trends in this area influence the demand for Machine Vision systems. Vision systems are applied in the highly automated production of raw materials, such as paper, cardboard, foils, soft plastic, and hard plastic. Also, in machines for cutting, casting, printing, welding, folding, and gluing, as well as in quality inspection, there is no way around optical technologies.

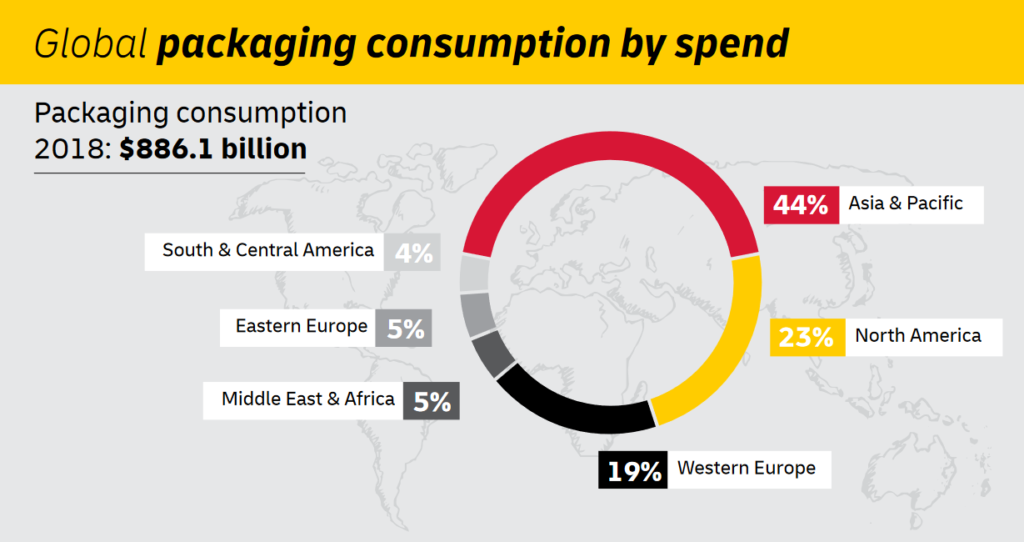

Packaging is Approaching a Trillion-Dollar Market Size

At the same time, Packaging is an area of high technological requirements. According to The Future of Packaging: Long-Term Strategic Forecasts to 2028 by Smithers Apex, the global packaging market was worth $906.59 billion in 2018. DHL mentioned a market size of $886 billion in 2018, likely due to a different slicing of the market by applications, e.g. logistics vs. products.

This sheer size of the global demand requires production processes to run at extremely high speed yet at challenging quality requirements. Line scan cameras and high-speed area scan cameras are demanded by vision systems for packaging. Such camera technology naturally comes with the need for high-end illumination.

Therefore, the value per system is often especially high in packaging-related applications, making it an attractive target market for Component OEMs, Machinery OEMs, and System Integrators.

Types and Purposes of Packaging

The report distinguishes three different types of packaging

- Primary packaging, i.e. the inner enclosure that is in direct contact with the product

- Secondary packaging, i.e. the outer enclosure and filler material designed to contain multiple primary packages and maintain their original condition

- Tertiary packaging consolidates multiple primary and secondary packages to facilitate handling, transport, and storage

The key purposes of packaging are:

- Protection

- Transportability

- Communication

- Brand experience

- Security and traceability

- Connectedness

In each application scenario, e.g. food vs. consumer electronics, pharmaceuticals vs. wafer shipments, different purposes are of different importance.

New Highs in Requirements and Packaging Sales from E-commerce

With the rise of e-commerce to $4.88 trillion by 2021 (Source: Smithers) the requirements on the tertiary but interestingly also on the secondary and primary packaging are changing.

Over 100 billion parcels are expected to be shipped worldwide in 2020, with B2B online retail expected to reach double the value of the B2C online market. Thus, Smart Warehousing and Omnichannel Logistics rely on Machine Vision for continuous tracking, automated handling, and transportation of goods.

The Impact of Trends in Packaging on Machine Vision

On a high-level, the given trends indicate various impacts on Machine Vision suppliers to the Packaging market:

- Price pressure on packaging: Companies will answer this price pressure by increasing the level of automation, throughput, and yield of their production lines. Machine Vision paves the way

- Demand for sustainable materials: This can mean new materials like bio-plastics made from seaweed, or recycled plastics. This is likely calling for new designs of vision systems, e.g. to detect specific defects in such novel materials.

- Delivering outstanding customer experience: This could mean that printing colors, surfaces, and shapes of packages need to be manufactured and inspected with even higher accuracies. Machine Vision is the enabling sensor modality behind.

- Adoption of Smart Packaging solutions: Use cases like self-monitoring pill blisters might experience a breakthrough in the mass market. From the standpoint of environmental sustainability, all Smart Packaging solutions that involve the use of electronic chips are not acceptable. Price points of rare earth minerals, copper, etc. in single-use packaging shall decide about the success of such approaches. Non-tactile, versatile, and powerful vision technologies, however, are well suited to add intelligence to standard packaging.

Would you like to learn more about the technical requirements, trends and market opportunities for Machine Vision companies in Packaging and Logistics?

Vision Markets is dedicated to supporting growth in Machine Vision and provides tailored Market Studies. Let’s ensure you make the right strategic decisions for the success of your business.

DO YOU WANT TO BE NOTIFIED ABOUT UPDATES ON TARGET MARKETS OF MACHINE VISION? Join the VisionCrunch community!